When designing fluid transport systems, you must consider how pipe diameter influences friction losses. As the diameter shrinks, you’ll notice a sharp increase in resistance and energy losses due to higher fluid velocities. This can complicate your efforts to maintain ideal flow rates. Understanding these dynamics is essential for effective system design, but there’s more to explore regarding the impact of material choice and flow conditions on overall efficiency.

Key Takeaways

You are trained on data up to October 2023

- Smaller pipe diameters result in higher fluid velocities, increasing friction losses due to greater resistance.

- Increased turbulence in smaller pipes exacerbates energy losses and pressure drops in fluid systems.

- Friction factors are inherently higher in smaller diameter pipes, leading to greater overall friction losses.

- Sharp bends and fittings in smaller pipes further contribute to increased friction losses and reduced flow efficiency.

- Maintaining larger diameters can significantly reduce turbulence and friction, enhancing system performance and efficiency.

Understanding Fluid Dynamics

Understanding fluid dynamics is essential when analysing how fluids behave in various systems. You need to take into account fluid velocity, as it directly influences pressure changes and flow characteristics.

When fluid travels through a conduit, turbulence effects can greatly impact energy losses. Higher velocities often induce turbulence, leading to chaotic flow patterns that increase friction losses.

The Relationship Between Pipe Diameter and Flow Rate

When you evaluate the flow rate of a fluid in a pipe, the diameter of that pipe plays an essential role in determining how efficiently the fluid can move. A larger diameter generally allows for a higher flow velocity, while smaller diameters can restrict movement, leading to increased friction losses.

Here are some key points to examine:

- Flow rate increases with larger pipe diameters.

- Smaller diameters require more pump energy to maintain flow.

- Pipe fittings can create additional turbulence, affecting flow velocity.

- Proper sizing of pipes is vital for peak system performance.

Factors Influencing Friction Losses

Various factors influence friction losses in a pipe system, and their impact can greatly affect overall efficiency.

One key aspect is pipe insulation; inadequate insulation leads to heat loss, increasing fluid viscosity and friction.

Additionally, the fitting types used in the system play a vital role. Sharp bends and changes create turbulence, further elevating friction losses.

Each fitting’s design affects flow direction and velocity, which can exacerbate these losses.

Calculating Friction Loss in Pipes

When calculating friction loss in pipes, understanding the impact of pipe diameter is essential. A larger diameter typically reduces friction loss, while flow rate considerations can greatly alter the dynamics of pressure drop.

Pipe Diameter Impact

Understanding how pipe diameter affects friction loss is essential for optimising fluid transport systems.

Smaller diameters increase friction losses due to higher fluid velocity, which can lead to inefficiencies.

Here are key considerations for pipe sizing:

- Friction Factor: Smaller pipes have higher friction factors, increasing resistance.

- Pressure Drop: A reduction in diameter increases pressure drop across the system.

- Flow Rate Limitations: Smaller pipes may restrict flow rate, impacting system performance.

- Energy Loss: Increased friction leads to higher energy costs for pumping.

Flow Rate Considerations

While calculating friction loss in pipes, it’s crucial to take into account the flow rate, as it directly influences both the velocity of the fluid and the resulting pressure drop.

To achieve flow rate optimisation, you need to analyse how velocity variations affect friction losses. Higher flow rates typically lead to increased velocity, which can heighten friction loss considerably.

Conversely, lower flow rates may reduce friction but can cause other issues like sediment build-up.

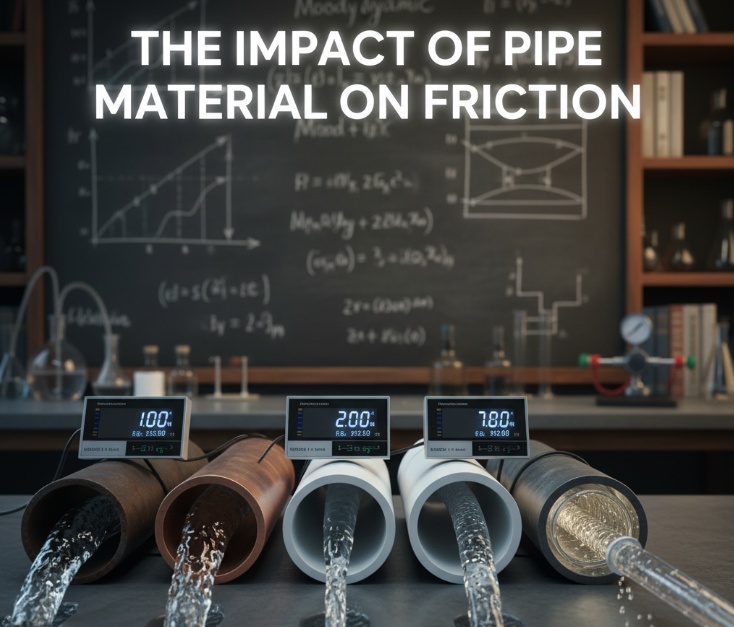

The Impact of Pipe Material on Friction

The material you choose for your pipes greatly affects friction losses due to factors like density and surface roughness.

Different materials exhibit varying levels of resistance to flow, impacting overall efficiency.

Additionally, the chemical resistance of the pipe material can influence its long-term performance and friction characteristics.

Material Density Effects

When selecting pipe materials, you must consider how material density influences friction losses in fluid systems. Density variations affect flow characteristics and energy efficiency, leading to significant implications for your design.

Here are key points to keep in mind:

- Higher density materials can lead to increased friction due to greater mass flow resistance.

- Lighter materials often have lower friction losses but may compromise strength.

- Different materials exhibit unique thermal properties that influence expansion and contraction.

- Material properties, such as elasticity and toughness, also interact with density to impact overall performance.

Choosing wisely can enhance system efficiency and longevity.

Surface Roughness Influence

Understanding how surface roughness affects friction losses is essential for optimising fluid flow in pipe systems. The surface texture of materials influences flow characteristics markedly. Rougher surfaces increase turbulence, thereby escalating friction losses. You need to evaluate material selection carefully to minimise these roughness effects.

| Material Type | Surface Texture | Friction Factor |

|---|---|---|

| PVC | Smooth | Low |

| Steel | Moderate | Medium |

| Cast Iron | Rough | High |

Selecting appropriate materials can help you achieve efficient fluid transport while keeping friction losses under control.

Chemical Resistance Factors

While selecting pipe materials, you must consider how chemical resistance impacts friction losses in fluid systems. The material’s chemical compatibility directly influences the efficiency of fluid transport, affecting overall performance.

Here are key factors to evaluate:

- Material Type: Different materials have varying resistance ratings against specific chemicals.

- Temperature Effects: Higher temperatures can reduce chemical resistance, altering friction characteristics.

- Fluid Composition: Mixtures can lead to unexpected interactions, impacting friction.

- Surface Treatment: Enhanced finishes may improve chemical compatibility and reduce friction.

Understanding these factors helps you minimise friction losses and optimise system performance.

Strategies to Minimise Friction Losses

To minimise friction losses in piping systems, you’ll first want to evaluate the impact of pipe diameter and material choice. Selecting larger diameters can greatly enhance flow optimisation by reducing turbulence.

Additionally, opting for smoother pipe materials aids in friction reduction, as rough surfaces increase resistance. Implementing streamlined fittings and minimising bends also contributes to decreased pressure losses.

Choosing smooth pipe materials and minimising bends can significantly reduce friction and pressure losses in piping systems.

Regular maintenance is crucial for keeping systems efficient, as debris buildup can exacerbate friction losses.

Finally, consider using flow rate adjustments to optimise efficiency, ensuring that your systems operate within their ideal parameters for maximum performance and minimal energy loss.

Case Studies: Real-World Applications and Results

When evaluating the effectiveness of different piping systems, case studies provide invaluable insights into real-world applications and results of friction loss management.

You can observe how various scenarios impact efficiency and performance:

- A municipal water system showed a 25% increase in energy costs due to friction losses in smaller diameter pipes.

- An industrial plant optimised its piping layout, reducing friction losses by 30%.

- A heating system realised improved temperature consistency after switching to larger pipes.

- A fire suppression system reduced response time markedly with optimised pipe diameters.

These real-world examples highlight the importance of selecting appropriate diameters for practical applications.

Conclusion

In the intricate dance of fluid dynamics, pipe diameter plays a pivotal role, akin to the narrow throat of a wind instrument amplifying sound. As you’ve learned, smaller pipes can stifle flow and inflate friction losses, turning efficiency into a fleeting whisper. By understanding these dynamics and employing strategic sizing and material choices, you can orchestrate a harmonious system that minimises energy loss, ensuring your fluid transport systems operate with the grace and power they deserve.