When you consider fluid dynamics, it’s vital to understand how pipe diameter impacts friction losses. As diameter decreases, fluid velocity and turbulence increase, leading to higher resistance against flow. This can greatly degrade system efficiency, especially under turbulent conditions. If you’re looking to optimise performance in your engineering designs, recognising these dynamics is essential. The implications of this factor could alter your approach to system design and energy consumption. What strategies might you employ to address these challenges?

Key Takeaways

- Smaller pipe diameters lead to increased fluid velocity, raising turbulence and friction loss significantly.

- Increased turbulence disrupts smooth flow, contributing to higher resistance in narrower pipes.

- The Darcy-Weisbach equation shows that pressure loss escalates with reduced diameter, affecting system efficiency.

- Higher friction losses in smaller pipes necessitate careful design considerations to optimise energy consumption.

- Implementing strategies like minimising bends can help mitigate friction losses in smaller diameter pipes.

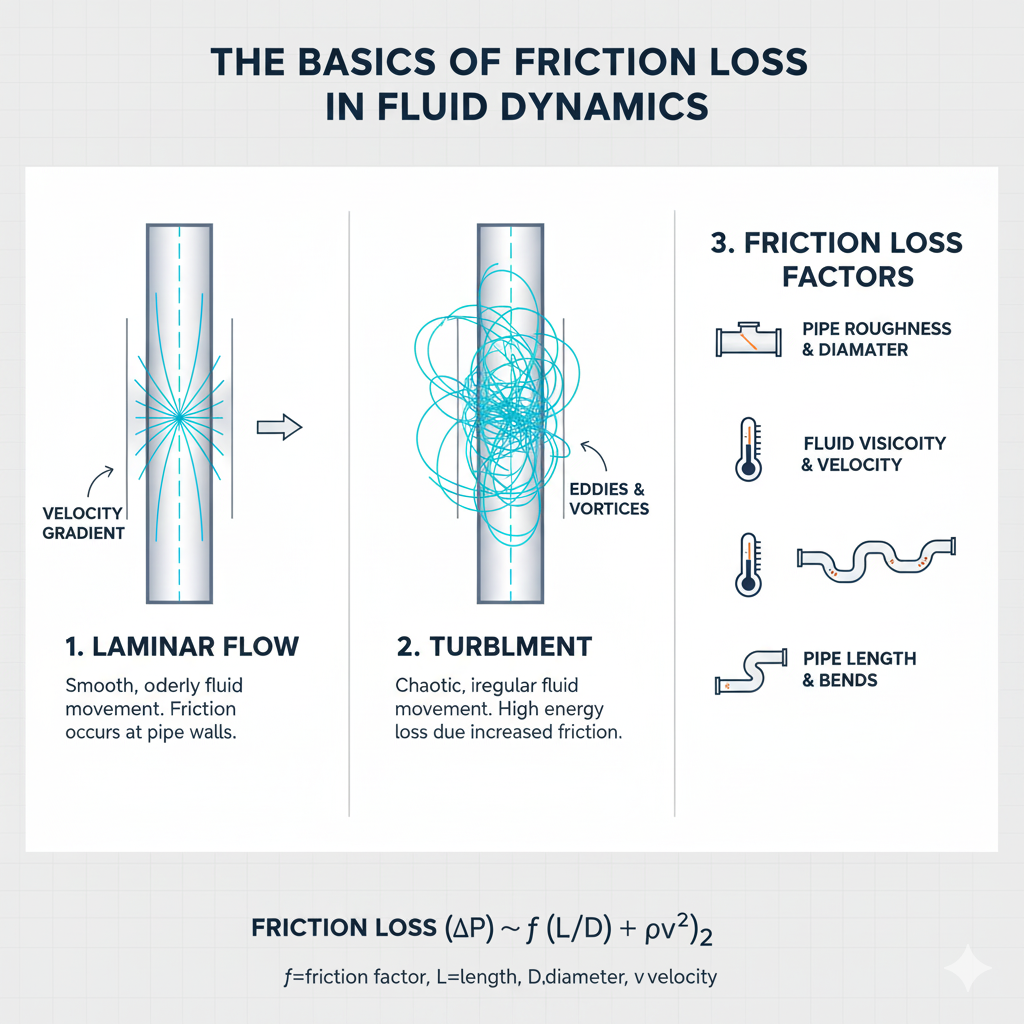

The Basics of Friction Loss in Fluid Dynamics

Friction loss is a critical concept in fluid dynamics, influencing the efficiency of fluid transport systems. When fluid flows through a pipe, its viscosity and flow regime—whether laminar or turbulent—play crucial roles in determining friction losses.

In turbulent flow, the interactions between fluid layers increase resistance, leading to higher friction loss compared to laminar flow. You’ll find that as fluid viscosity increases, the friction loss also rises, further complicating flow efficiency.

Understanding these dynamics allows you to optimise systems, ensuring you minimise energy consumption while maximising fluid throughput. Your awareness of these factors can greatly enhance system performance.

Impact of Pipe Diameter on Flow Resistance

As you decrease the diameter of a pipe, the flow resistance typically increases due to the heightened velocity and turbulence of the fluid.

This phenomenon, known as diameter effects, directly influences pipe flow characteristics. A smaller diameter constricts the fluid, causing it to move faster, which in turn raises friction losses.

The turbulence generated can disrupt smooth flow, resulting in additional resistance. Consequently, you may experience significant energy losses as the fluid navigates through narrower passages.

Turbulence can hinder smooth fluid flow, leading to increased resistance and notable energy losses in narrow passages.

Understanding these dynamics is essential in optimising pipeline design and ensuring efficient fluid transport within any system.

Calculating Friction Loss: Key Formulas and Concepts

While designing fluid transport systems, understanding how to calculate friction loss is crucial for optimising performance.

To determine friction loss, you can use the Darcy-Weisbach equation: ΔP = f * (L/D) * (ρ * v²/2), where ΔP is the pressure loss, f is the friction factor, L is the pipe length, D is the diameter, ρ is the fluid density, and v is the flow rate.

Remember, as flow rate increases, friction loss also rises, particularly in smaller diameter pipes.

Accurate calculations guarantee efficient designs, helping you minimise energy costs and improve overall system reliability.

Practical Implications for Engineering Design

Understanding the implications of friction losses in smaller diameter pipes is essential for effective engineering design. You must consider how these losses impact system efficiency and performance.

Design considerations should include flow rates and pressure drops, ensuring that your system meets operational requirements. Additionally, material selection plays a significant role; different materials exhibit varying resistance to friction, influencing overall energy consumption.

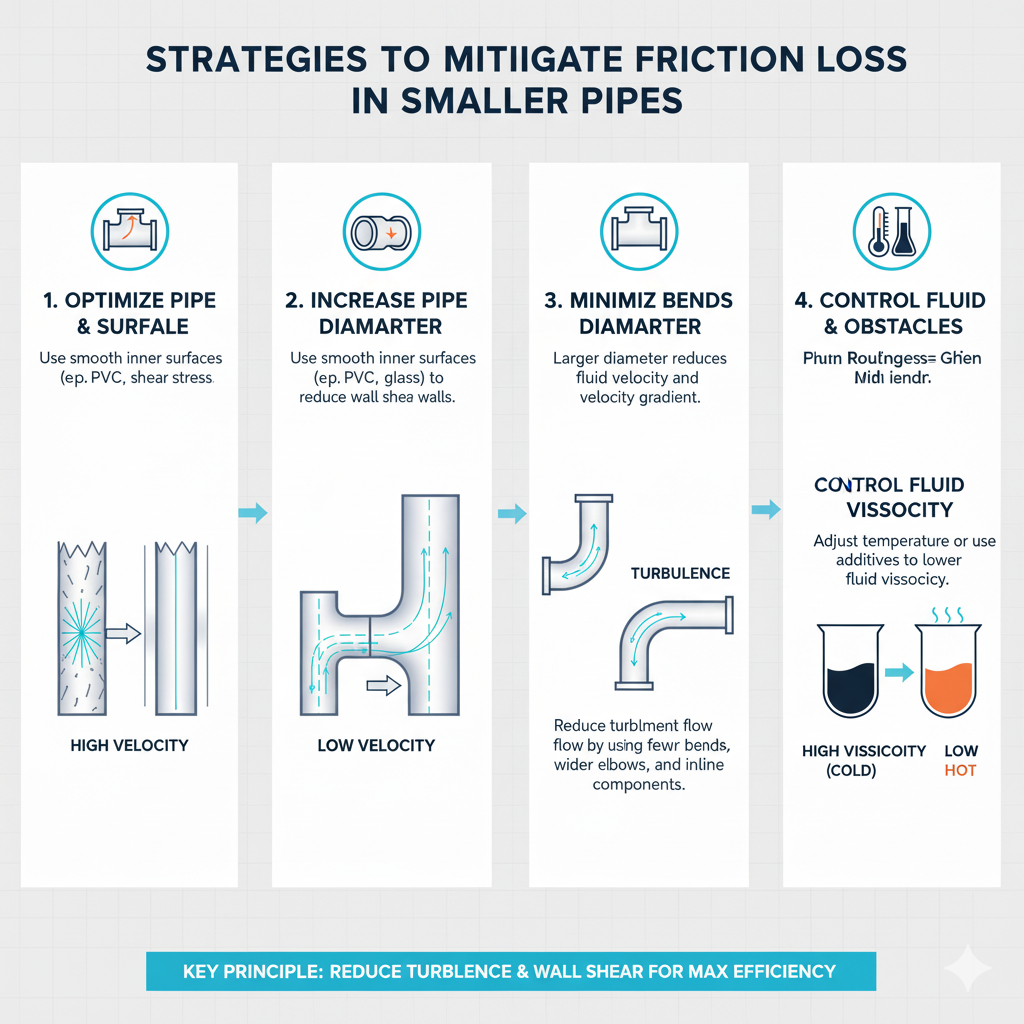

Strategies to Mitigate Friction Loss in Smaller Pipes

Several effective strategies can help mitigate friction loss in smaller diameter pipes, enhancing system performance. You can implement pipe insulation to maintain temperature and reduce viscosity, improving flow. Additionally, using flow additives can optimise fluid characteristics, minimising turbulence and friction.

| Strategy | Description | Benefits |

|---|---|---|

| Pipe Insulation | Insulates pipes to maintain fluid temperature | Reduces viscosity, improves flow |

| Flow Additives | Chemical additives to enhance flow properties | Decreases turbulence, lowers friction |

| System Design Adjustments | Optimise layout and fittings | Minimises bends, reduces losses |

Conclusion

To sum up, it’s clear that smaller pipe diameters lead to significant friction losses, a truth that’s critical for engineering design. By understanding the relationship between pipe diameter and flow resistance, you can make informed decisions that enhance system efficiency. Have you considered how even slight changes in diameter could impact your project’s energy consumption and performance? By implementing strategies to mitigate these losses, you can optimise your design and achieve better outcomes in fluid dynamics.